Contact models for friction, wet cohesion, sintering

Since joining the University of Twente, my interest has expanded from developing computational solvers to their application in the field of particulate materials. I have studied such systems on all scales, starting with the contact mechanics of individual particles to rheological models for large-scale applications. I have developed, applied, and validated contact models for friction, plasticity, sintering and bonding, and wet and dry cohesion.

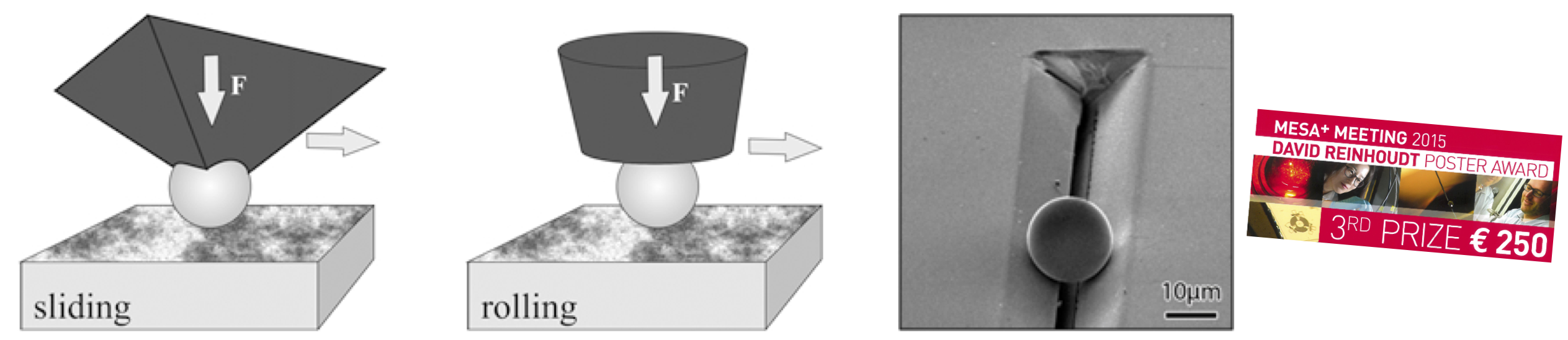

In collaboration with the University of Siegen, frictional forces between small borosilicate particles were measured in a nanoindenter setup with very high accuracy [J13,C3]. The data was then used to define and validate an objective model for sliding, rolling and torsional friction.

In particular, a novel method was introduced to measure torsion friction. I have received a poster award from the MESA+ Institute for Nanotechnology for this work.

Measuring rolling, sliding and torsion friction in single particle experiments [J13].

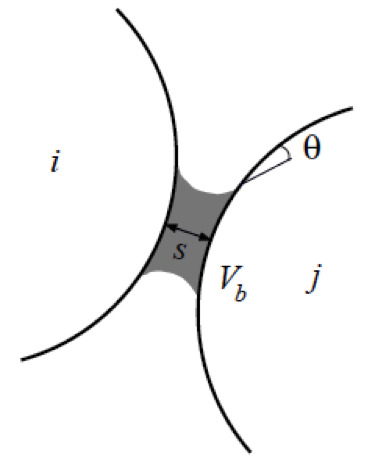

Cohesion due to humidity and added liquids plays an important role in many applications of particulate matter. Liquid bridges form at the contacts of wetted particles, causing adhesion that leads to clumping and added shear stress [J14,C5,C4]. Furthermore, liquid migration causes inhomogeneities in the liquid distribution. I am studying this behaviour with my PhD student S Roy, in collaboration with R Schwarze in Freiberg and S Turek in Dortmund (DFG-STW project 12272).

In most realistic situations, where particles come in contact, contact properties depend on pressure, temperature or time. Sintering is one such phenomenon. Sintering starts with many separate powder particles that are, for example, attracted by electrostatic forces, bound together by capillary forces, or squeezed together by strong pressure. Leaving them alone for long time, diffusion will set in and change the contact properties, building up solid bonds between the particles. At elevated temperatures, the sintering accelerates and a solid, possibly porous and fragile agglomerate is formed rapidly from the originally isolated particles.

The goal of the DFG project LU 450/10 Particles in Contact: Sintering is to model the particles in contact, before the particles lose their identity. For this, temperature- and pressure-dependent contact models have been developed [S5], in parallel to contact measurements of M Kappl at the Institute of Polymer Physics, MPI Mainz. The many-particle simulations will then be adapted to the materials used and experimentally validated. Then, micro-macro transition methods are used to obtain better theoretical constitutive relations for a macroscopic description, based on the mechanics/physics of the contact scale.

Indenting of a weakly sintered granular bed. The sintering is so weak, that particle contacts easily break.