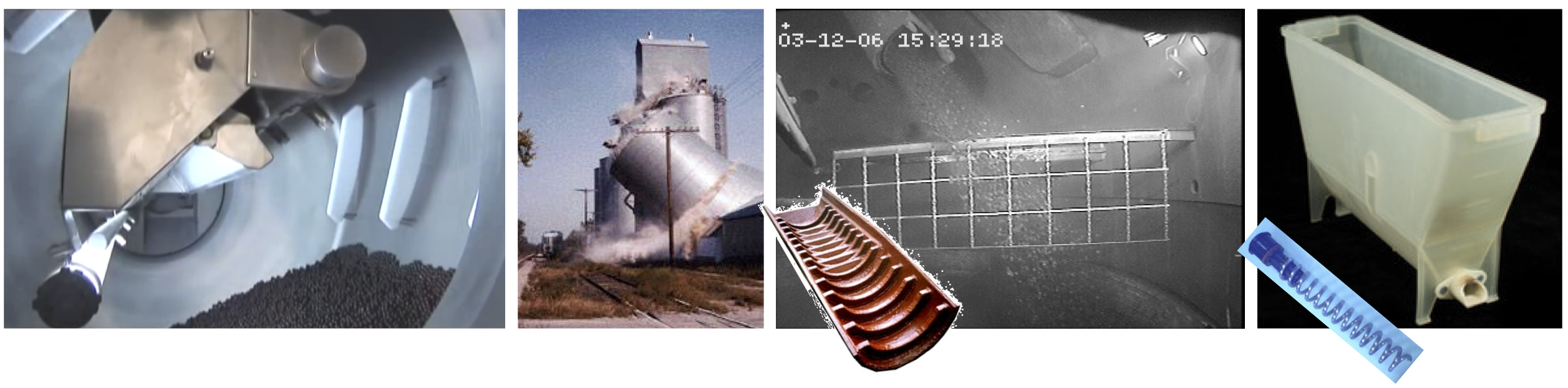

Industrial applications

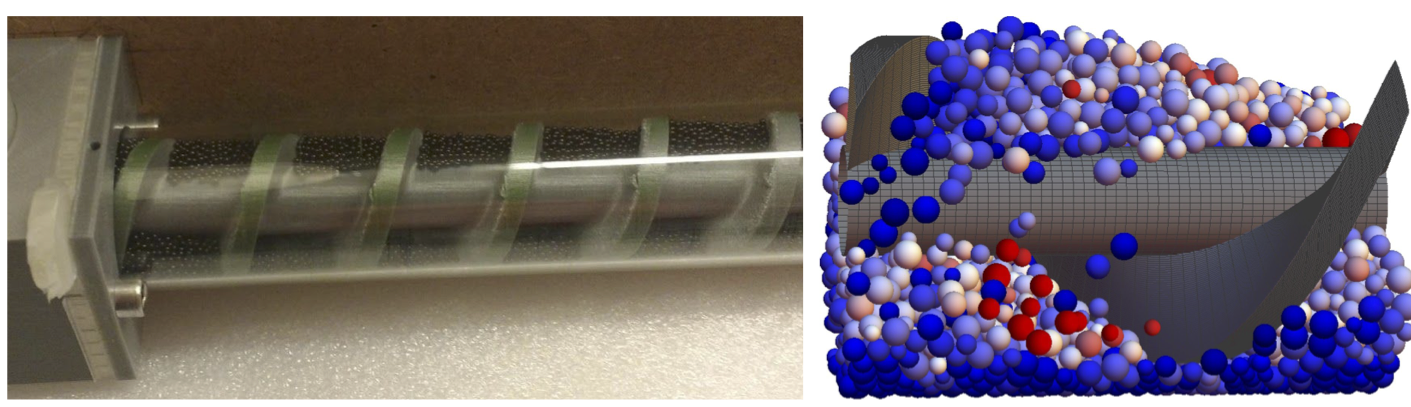

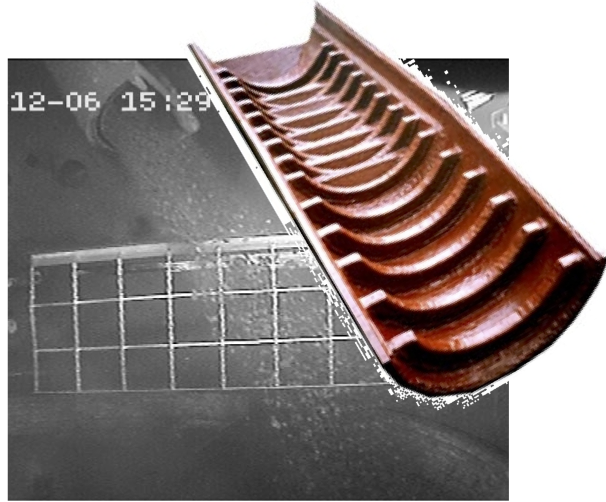

To study granular materials, I co-founded MercuryDPM [J3,C7,C2,N3,N2], a open-source particle simulator, of which I am the lead developer. The tool is unique in its capability to solve highly polydisperse mixtures and complex geometries. As a result, the code has been applied in several industry- supported projects, see figure. In addition, I have trained and consulted our industrial partners via our spin-off company MercuryLab, which has often led to follow-up academic work.

Industrial applications (left to right): rotating drums, silo flow (Edinburgh), rotating blast-furnace chute (Tata Steel), vending machine canister (Nestle).

Recent developments in 3D printing and Additive Manufacturing, which is considered as part of the next industrial revolution, enable the fabrication of individualized serial products. To date, none of the conventional techniques like e.g. selective laser sintering allow the production of interconnected porous polymer scaffolds with a variety of pore sizes and reproducible morphology to stimulate the formation of new tissue. This mainly forces the attention of scientists to the initial stage of sintering, where the porous structure is characterized by the formation of necks between individual particles. Achieving the initial stage of polymer particle sintering, without significant temperature increase in the bulk of each particle, requires a fundamental understanding of sintering under varying temperature-, size-, and time-conditions. I am studying this together with M Kappl at the Institute of Polymer Physics, MPI Mainz [C9]

Beginning of 2017, I will start research on modelling agglomeration processes (tabletting and sintering) of particulate materials. Agglomerates will be modelled using a mesoscale approach. Funding for this project has just been approved, and the available PhD positions will be posted soon.

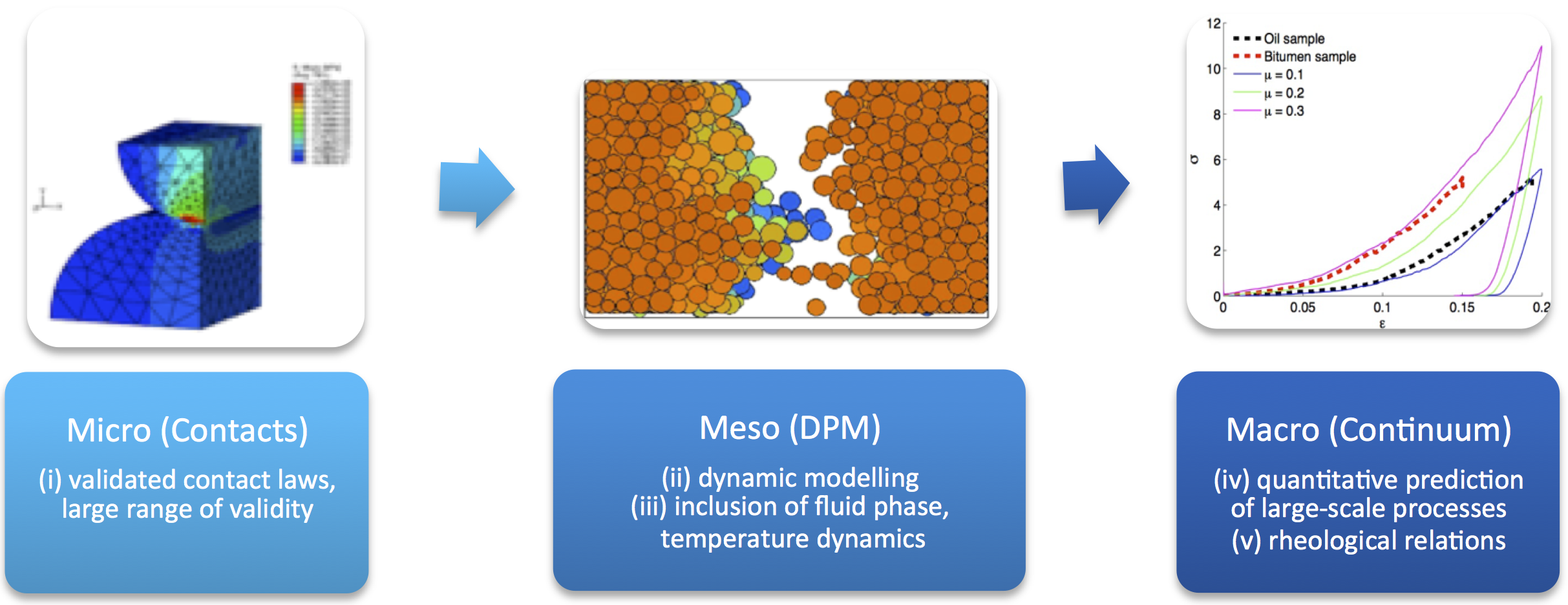

Schematic overview of the meso-scale modelling philosophy: The meso-scale model is based on (microscopic) contact information to predict (macroscopic) processes such as Selective Laser Sintering.

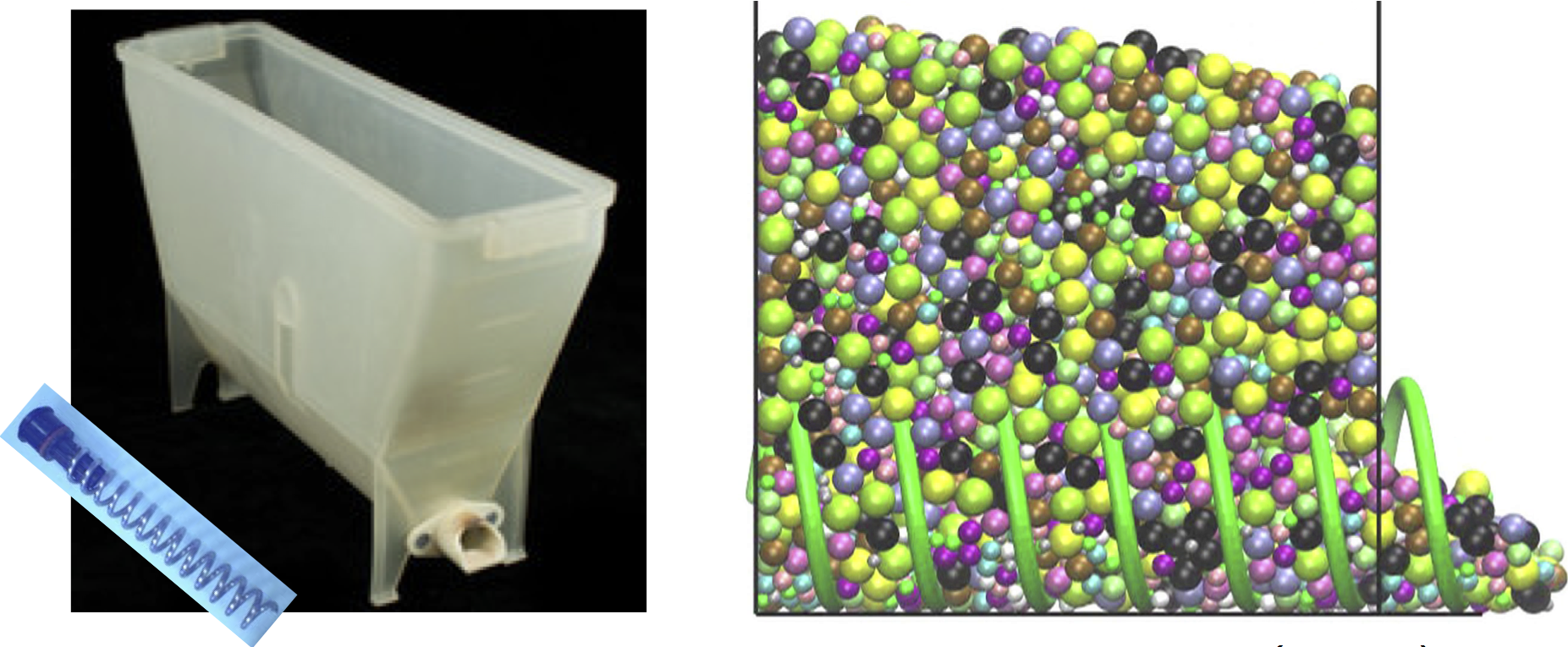

Vending machine canister for cohesive powder.

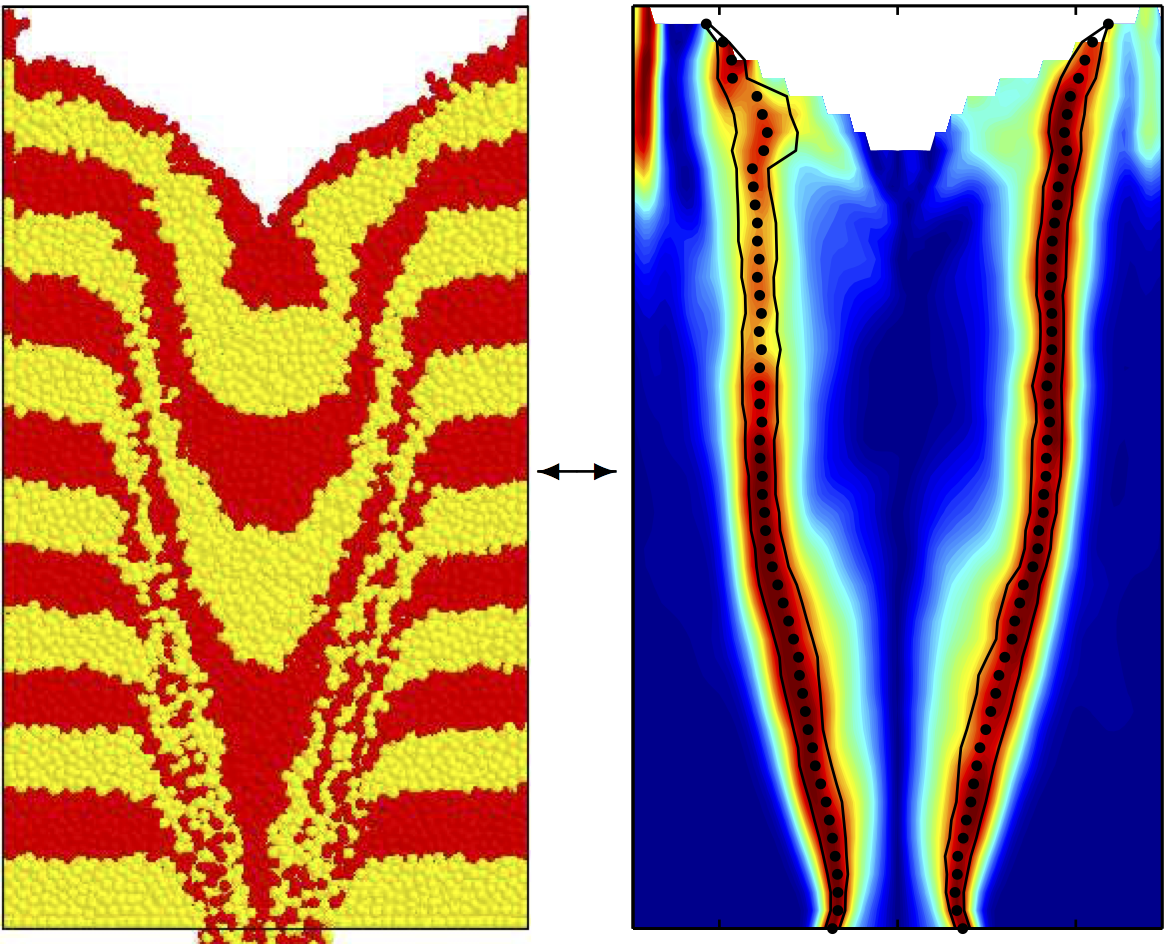

Flow through a 2D model silo; shear zones are clearly visible.

3D-printed scale model of screw feeder vs Particle flow simulation using MercuryDPM.

A rare view into the iron-ore melting furnace shows the inflow of pellets from an inclined, rotating chute during an inspection cycle. Improved control of the inflow of such granular matter is desired (Photo courtesy: Corus).