Multiscale Modelling: Constitutive modeling and Coupling

Particulate materials can be viewed as multiscale-materials: On the micro-scale, they consist of discrete particles interacting with each other and the surrounding geometry; on the macro-scale, they can be viewed as a continuous bulk material. The same two scales exist for solids and fluids: however, the micro- and macro-scale of particulate materials differs only by a few orders of magnitude. Thus, many macroscopic phenomena in particulates depend on the amount of scale separation. This has so far prevented the development of a general macroscopic continuum model for particulate materials exists (as exists for solids and fluids).

However, continuum models for particulates can be developed for specific situations. To do this, I have developed a new and efficient coarse-graining technique (CG) to couple micro- and macro-scale models for particulate flows. In [J3,J5], I used CG to determine and calibrate closure relations for shallow granular flows from small-scale DPM simulations. A depth-averaged model was chosen, as this allows highly efficient large-scale simulations. I further applied CG to determine an objective rheological model for rapid granular flows [J9]. This work was extended to nanofluidic channels [J6], which have widespread applications in biology, chemistry and medicine. I am now studying the rheology of wetted and sintered materials. Finally, I extended the CG technique to multi-phase flows [J18,C1] to study segregation [J7].

The concept of CG can also be applied to directly couple the micro- and macroscopic models for particulate materials. This will be an important aspect of my future research.

I have developed a new and efficient coarse-graining (CG) technique to couple micro- and macro-scale models for particulate flows. The method is implemented in MercuryDPM and widely used. CG extracts local macroscopic quantities (density, velocity, stress) from particulate data. Unlike conventional techniques, it conserves mass and momentum exactly, even at external boundaries and in mixtures. This method is robust in the sense that the resulting variables are independent of the averaging length scale within a predetermined range [J17,J9]. With this computational tool, it is possible to calibrate the material properties based on experimental observations and to quantitatively predict the behavior of granular assemblies, which is crucial for industrial applications.

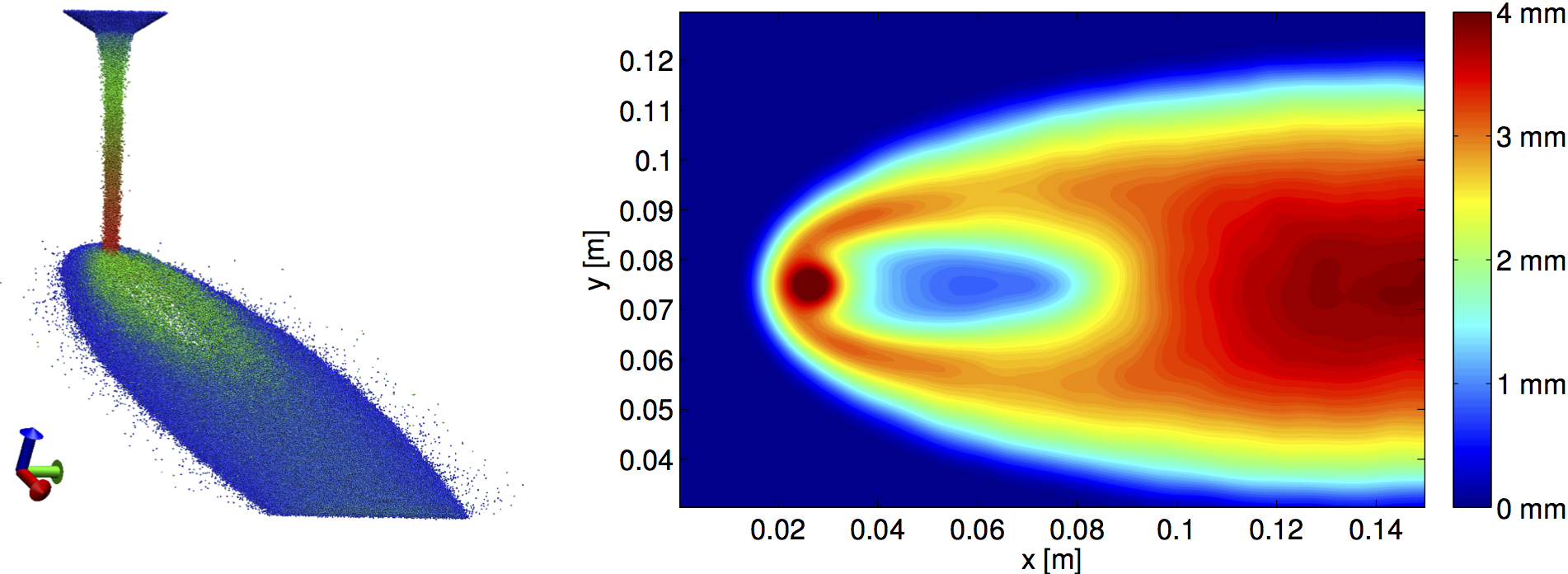

Left: Flow from a funnel onto an inclined plane, simulated in MercuryDPM.

Right: Flow height evaluated using the micro-macro transition method.

In [J3,J5], I used the CG method described above to determine and calibrate closure relations for shallow granular flows from small-scale DPM simulations, see figure. Shallow flows have many applications in the bulk handling industry (such as conveyors and chutes) and geotechnics (avalanches). A depth-averaged model was chosen, as this allows highly efficient large-scale simulations.

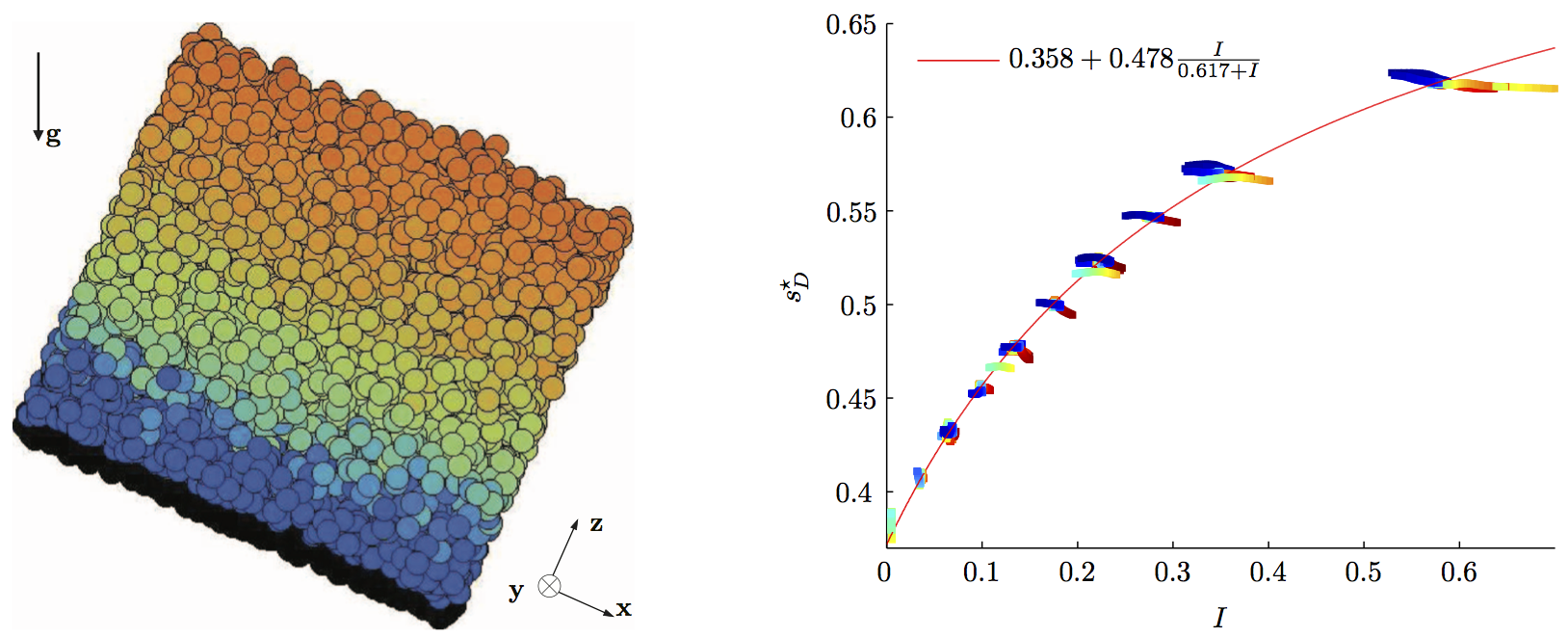

Left: Small-scale simulation of steady uniform granular flows in a periodic chute [5].

Right: Friction as a function of the inertial number.

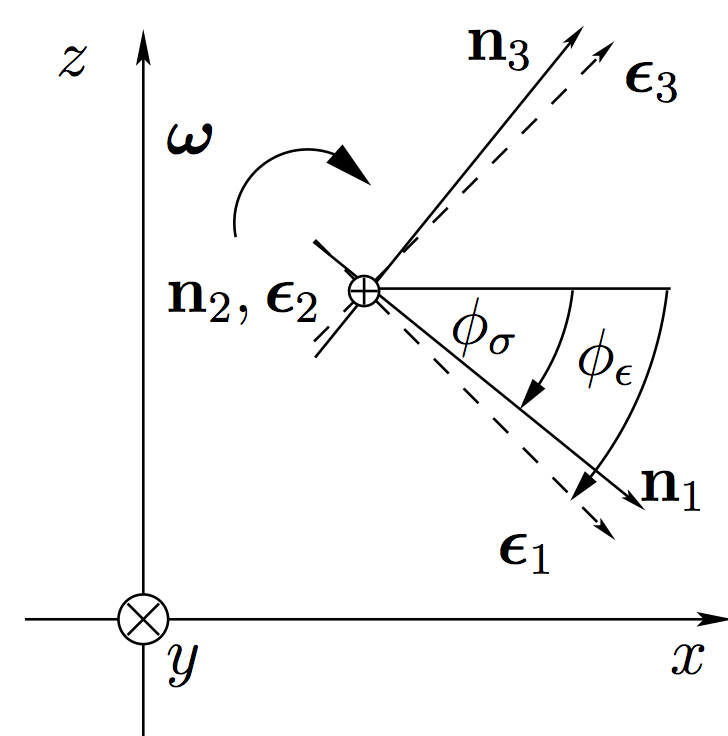

The maximum eigendirections of stress and strain in the shear plane are non-aligned.

In [J7], I have formulated a rheological model for rapid particulate flows (such as avalanches or chute flow), using objective invariants of the stress and strain tensors. The common assumption of collinearity between the stress and strain tensor was found to be a good approximation, but becomes less accurate for rapid flows, where the vorticity of the flow creates a lag between the orientations of the stress and strain tensors (see figure).

Flow of argon gas through a nano-size channel.

The goal of this project is to study the non-Newtonian transport properties of such atomistic fluids (see figure). We were the first to apply coarse graining, originally developed for particulate flows, to atomistic flows [J6]. The use of CG allowed us to investigate local properties, such as the effect of wall-fluid interaction, surface roughness and wall-morphology on the flow behavior.

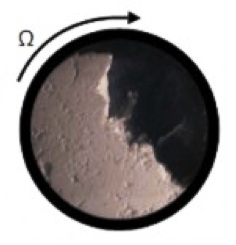

Cohesive, wet material in a rotating drum.

Cohesion due to humidity and added liquids plays an important role in many applications of particulate matter. It strongly changes the rheological behaviour of the material, leading to increased shear stress, agglomeration, and reduced segregation. Furthermore, liquid migration causes inhomogeneities in the liquid distribution. I am studying this behaviour with my PhD student S Roy [J14,C5,C4].

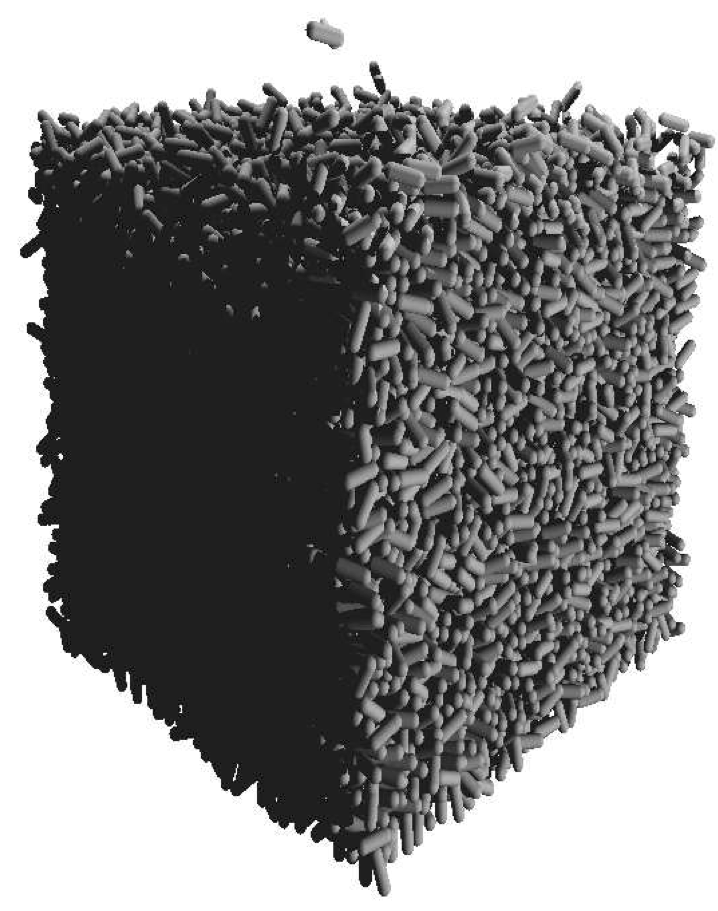

Rod-shaped particles flowing over a flat inclined surface.

Shape plays an important role in particulate bulk behaviour. I have recently started to study this behaviour in collaboration with RC Hidalgo (Navarra), by looking at spherocylindrical particles in chute flow [C8].

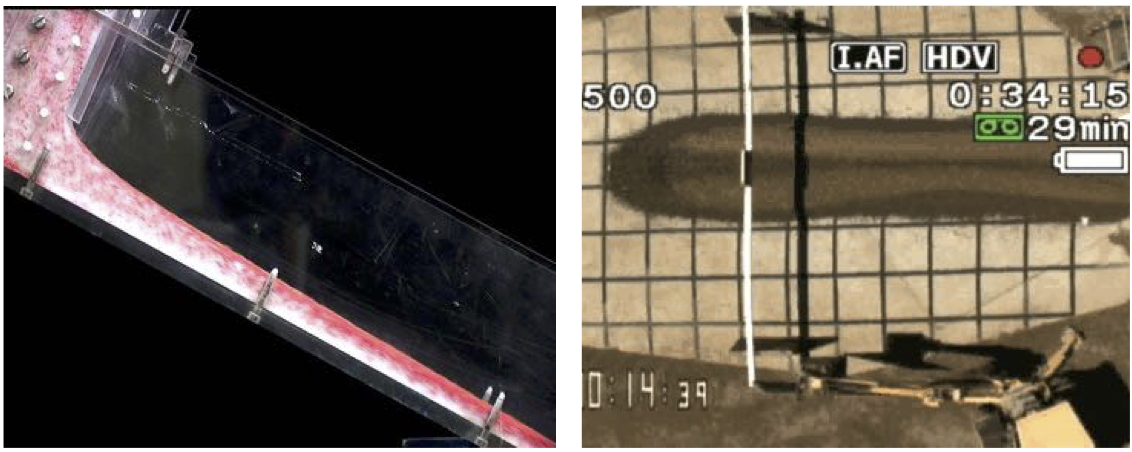

(Left) Segregating chute flow, with the larger, red particles rising to the surface.

(Right) Elongated flow front caused by the formation of sidewalls/levees from large, more frictional particles.

Predicting the behaviour of hazardous natural granular flows (e.g. snow slab avalanches, debris- flows and pyroclastic flows) is vital for an accurate assessment of the risks posed by such events. This behaviour is strongly affected by the segregation that occurs in the dense flow regions of these flows [J19,J12,J10,J7]. Segregation causes the larger particles to rise to the surface (left figure), from where they are transported to the front. This leads to fingering/levee formation and bulbous head formation (right figure), both of which increase the runoff and speed of an avalanche.